The Jobsmart air compressor is a reliable and essential tool for any DIY enthusiast or professional contractor. It provides the necessary power to run pneumatic tools, inflate tires, and perform a wide range of tasks around the home or job site. To keep it functioning at its best, it’s important to understand the various parts of the Jobsmart air compressor and how they work together.

One of the key components of the Jobsmart air compressor is the motor. This powerful device is responsible for driving the compressor pump, which generates and compresses air for use in various applications. The motor needs to be properly maintained and sometimes replaced if it breaks down or becomes worn out.

Another crucial part of the Jobsmart air compressor is the compressor pump. This pump is responsible for drawing in air and compressing it, which is then stored in a tank until it is needed. The compressor pump is typically made up of cylinders, pistons, and valves, all of which play a role in the compression process. It’s important to regularly inspect and clean these components to ensure optimal performance.

In addition to the motor and compressor pump, the Jobsmart air compressor also includes various other parts such as a pressure switch, air tank, pressure gauge, and safety valve. These components work together to regulate the pressure, store compressed air, and ensure safe operation. Understanding how these parts fit into the overall system can help diagnose and troubleshoot any issues that may arise.

In conclusion, the Jobsmart air compressor is a versatile tool that relies on a variety of components to function properly. By familiarizing yourself with the parts and their functions, you can effectively maintain and repair your Jobsmart air compressor, ensuring it continues to deliver reliable performance for years to come.

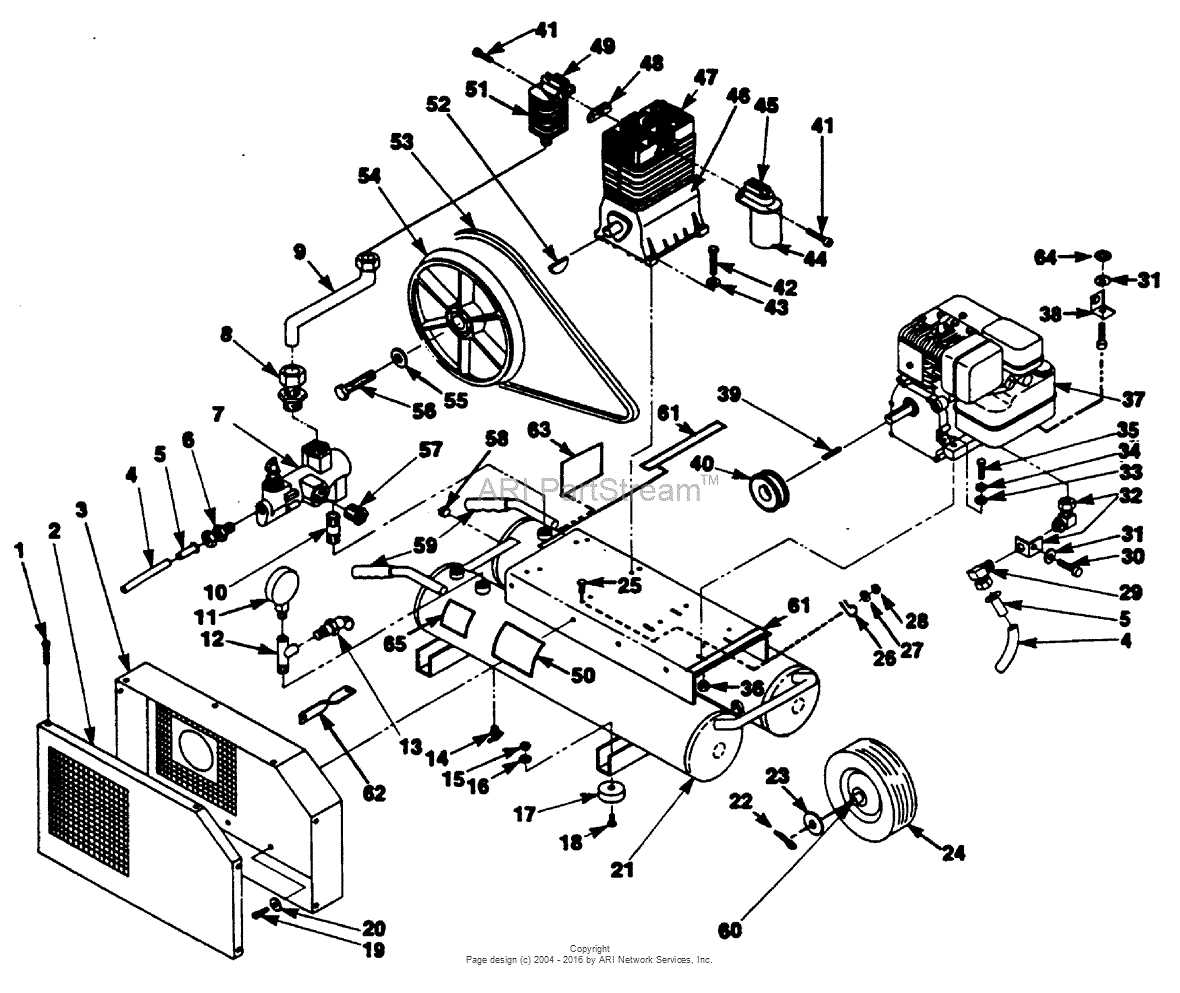

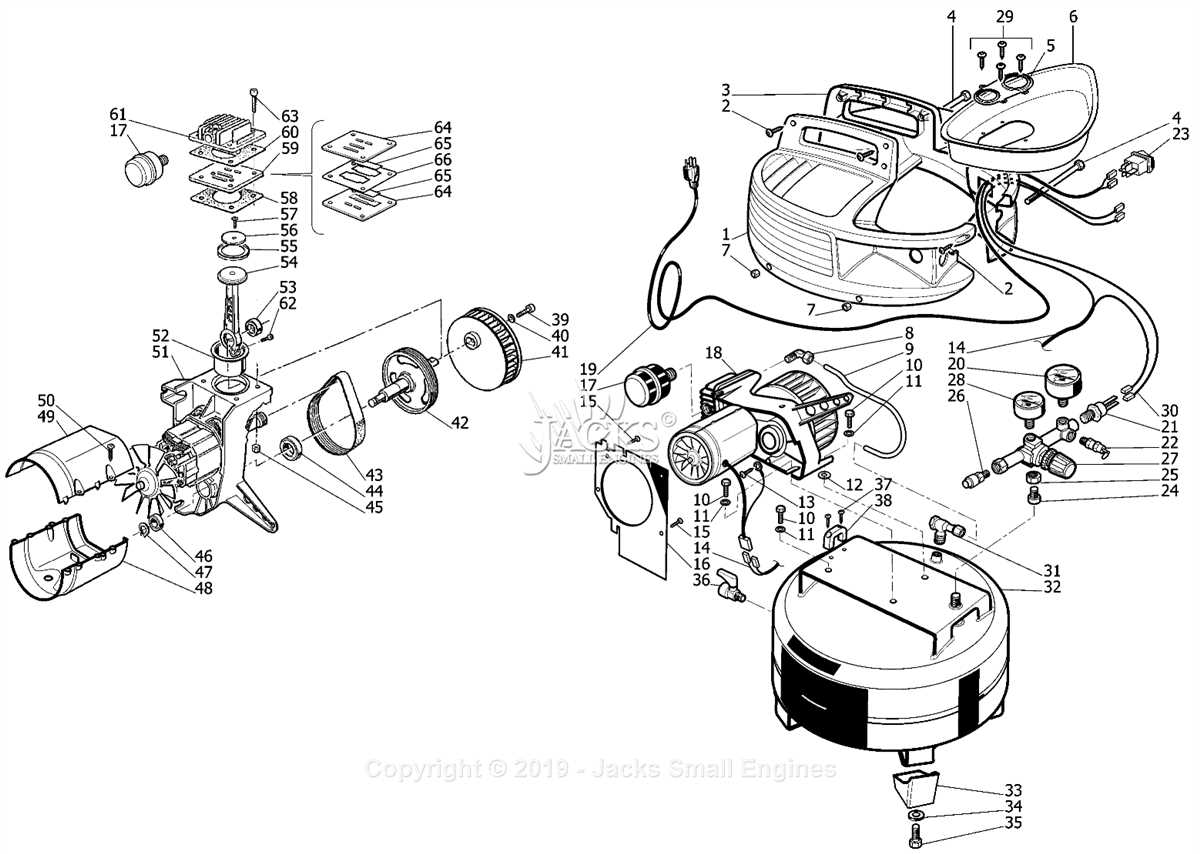

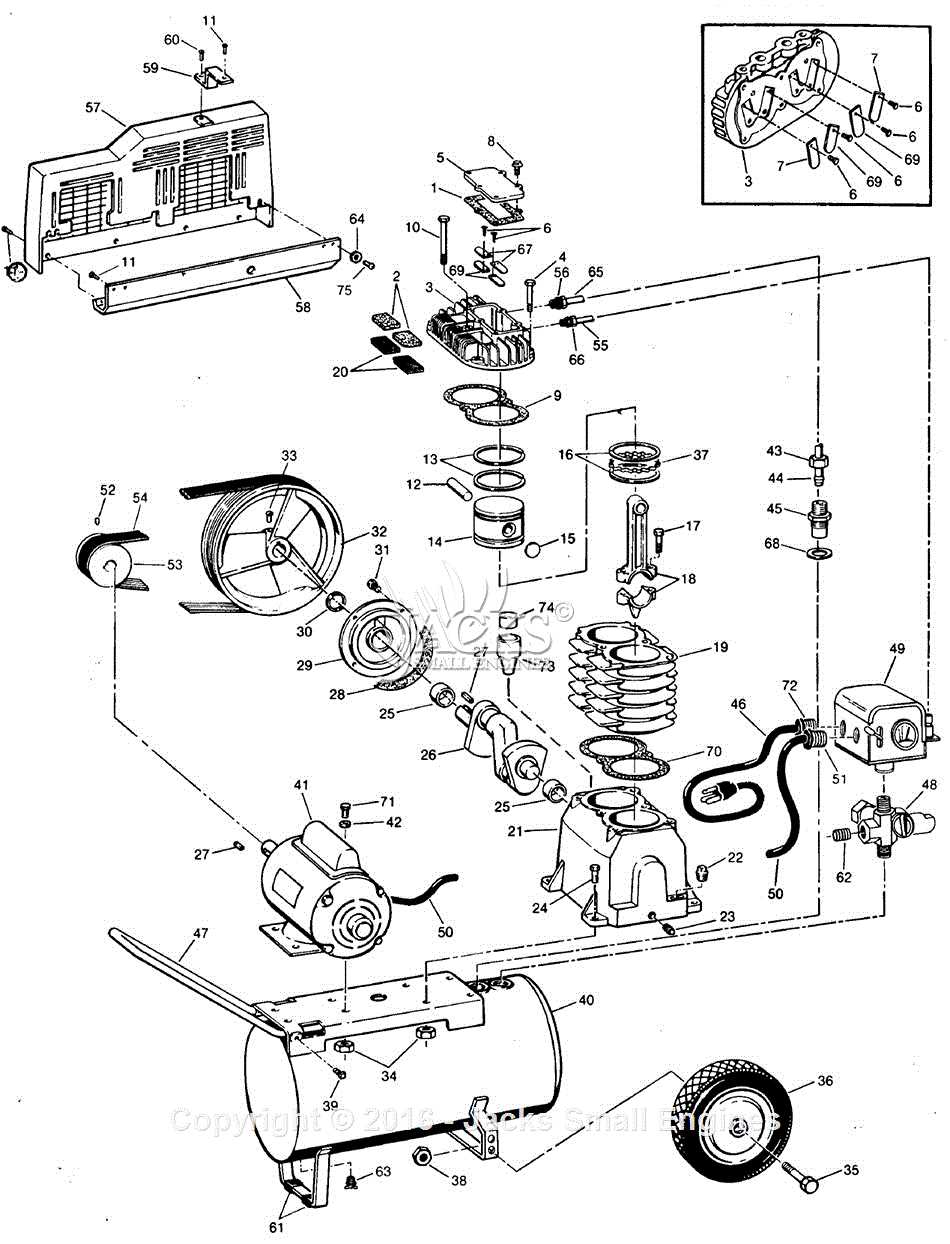

Jobsmart Air Compressor Parts Diagram

If you are in need of Jobsmart air compressor parts, it can be helpful to have a diagram to reference. This diagram can help you identify the specific parts you need, allowing you to easily locate and order them. A Jobsmart air compressor parts diagram is a visual representation of all the components that make up the air compressor, including the motor, tank, pump, and other essential parts.

Having a Jobsmart air compressor parts diagram can be particularly useful if you are performing maintenance or repairs on your air compressor. It allows you to see how all the parts fit together and how they interact with each other. This can help you troubleshoot any issues you may be having and ensure that you are replacing or repairing the right components.

Some common parts that may be included in a Jobsmart air compressor parts diagram are the pressure switch, pressure gauge, safety valve, compressor pump, intake filter, and motor. The diagram may also include labels or numbering to make it easier to identify each part. It is important to note that the specific parts and layout may vary depending on the model and type of Jobsmart air compressor you have.

If you are unable to find a Jobsmart air compressor parts diagram online or in the owner’s manual, you may want to reach out to the manufacturer or a trusted retailer that sells Jobsmart air compressors. They may be able to provide you with a diagram or assist you in identifying the specific parts you need.

Understanding the Basics of a Jobsmart Air Compressor

An air compressor is a vital tool in various industries and applications, providing a reliable and efficient source of compressed air for tasks such as powering tools, inflating tires, and operating machinery. The Jobsmart air compressor is a popular choice among professionals and DIY enthusiasts due to its durability and performance.

The Jobsmart air compressor consists of several essential parts that work together to compress air and deliver it for various uses. These parts include the motor, pump, tank, pressure switch, regulator, and gauges. Understanding the functionality of each part helps in operating and maintaining the air compressor effectively.

- The motor is the power source of the air compressor and provides the energy to run the pump. It converts electrical energy into mechanical energy to drive the pump.

- The pump is responsible for compressing air by drawing in atmospheric air and compressing it to higher pressure. It typically consists of pistons, cylinders, and valves that facilitate the air compression process.

- The tank is a storage container that holds the compressed air. It allows for the accumulation of a sufficient amount of compressed air that can be used when needed.

- The pressure switch is a safety feature that automatically controls the operation of the air compressor by turning it on and off at specific pressure levels. It ensures that the air compressor operates within safe pressure limits.

- The regulator controls the output pressure of the compressed air. It allows the user to adjust the pressure according to the specific requirements of the task or tool being used.

- Gauges are used to monitor the pressure levels in the tank and the output pressure of the compressed air. They provide real-time information and help in maintaining optimal performance.

By understanding the basics and functionality of these parts, users can operate and maintain their Jobsmart air compressor efficiently. Regular maintenance, such as checking and replacing worn-out parts, lubricating moving components, and keeping the air compressor clean, ensures its longevity and reliable performance.